Fire protection when building with wood: maintenance of electrical function and fire insulation

Ever more construction projects are being performed with wood, because the material is sustainable, cleaner and considerably lighter than other materials, such as reinforced concrete. However, besides these benefits, there is a huge disadvantage: Wood can burn. Thus, it seems something of a paradox to create buildings with complex fire protection with wood. However, the trend towards wooden construction must not be impeded by fire protection. After all, wood behaves relatively favourably in the event of fire. A layer of charcoal forms on the surface facing the fire, protecting the wood below against oxygen and thus preventing further burning.

OBO Bettermann provides fire protection solutions for timber construction with its product portfolio, offering various solutions that achieve important protection aims in the event of fire, even on wooden constructions: namely, the maintenance of electrical function and fire sections.

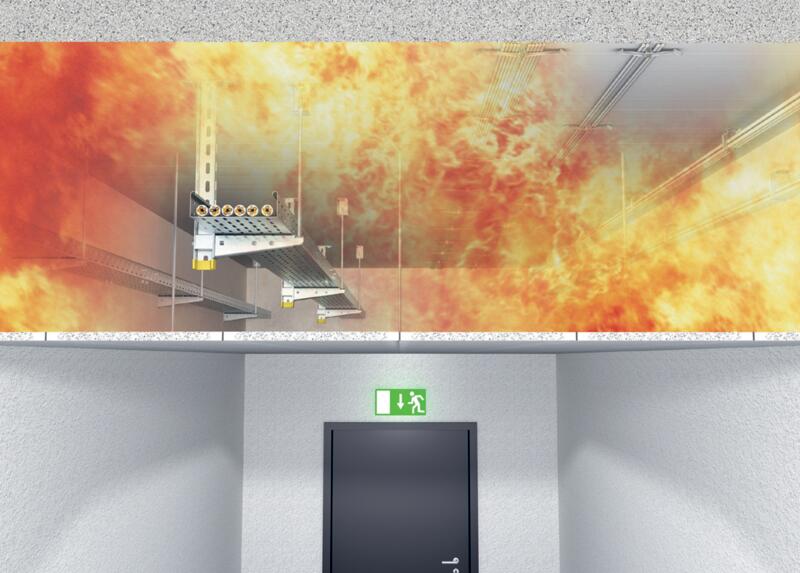

Maintenance of electrical function in wooden constructions

In the event of a fire, the functioning of technical equipment, such as emergency lighting, escape route signs, fire alarm systems or smoke extraction systems, must be maintained. This is why ensuring the continued supply of power to these systems is one of the most important aims in the event of fire. This aim is referred to as maintenance of electrical function. It is necessary to maintain the function of technical equipment for the following buildings and areas: hotels and restaurants, shops, meeting places and tower blocks. Following the timber construction trend, more and more wooden components, wooden ceilings and load-bearing elements made from wood are being installed in these buildings. Fire protection and, as a rule, the maintenance of electrical function are essential here. But thanks to the positive properties of timber in the event of fire and the use of suitable products, the maintenance of electrical function can also be ensured in wooden constructions.

OBO offers various solutions for fastening cable systems to wooden components while ensuring the maintenance of electrical function, such as centre suspensions or special disc-head screws for wood such as disc-head screw 6x60. The effectiveness of OBO products for the maintenance of function is certified in a fire protection survey by the IBB engineering office and the engineers Dr Peter Nause and Cord Meyerhoff.

DIN 4102 Part 12: crucial for the maintenance of electrical function

The layer of charcoal that forms on the wooden component in the event of fire protects the wood beneath against the supply of oxygen, thus preventing further burning. The unburned residual cross-section can easily be determined, taking the necessary component dimensions for secure fastening of cable support systems into account. This enables fastening while also maintaining electrical function according to DIN 4102 Part 12. DIN 4102 describes the “fire behaviour of building materials and building components”, while Part 12 defines the functional integrity of maintenance of electric cable systems as well as the requirements and testing thereof.

Requirements for fire protection when installing cable support systems on wooden components

Wooden components, unprotected in a fire protection sense, must fulfil some basic requirements so that cable support systems with the maintenance of electrical functionality can be installed in them:

- Solid wood is the most suitable type of wood for installing cable support systems. For example, cable support systems can be attached to glued laminated timber or laminated wood.

- Calculatory proof for the basic state of use must be provided. This is why it is relevant for the installation of cable support systems with the maintenance of electrical function, as it proves that the statics of the wooden component are sufficiently dimensioned for the building.

- Hot measurement is used to determine the carrying capacity of support structures in the event of fire. This calculatory method clarifies the extent to which the component must be dimensioned beyond the basic state of use so that the core of the burnt item can support the intended load in case of fire.

If the requirements for the wooden component have been fulfilled, the type of cable support system must be specified. OBO offers a tailored product portfolio, which has been tested and continuously expanded over time, also featuring accessories for safe anchoring and fastening to load-bearing wooden components. This includes our fire protection plate, made of water and frost-resistant fibreglass lightweight concrete, mineral fibre plate with ablation coating, special fire protection cushions and our fire protection mortar.

Fire sections prevent fire from spreading in wooden constructions

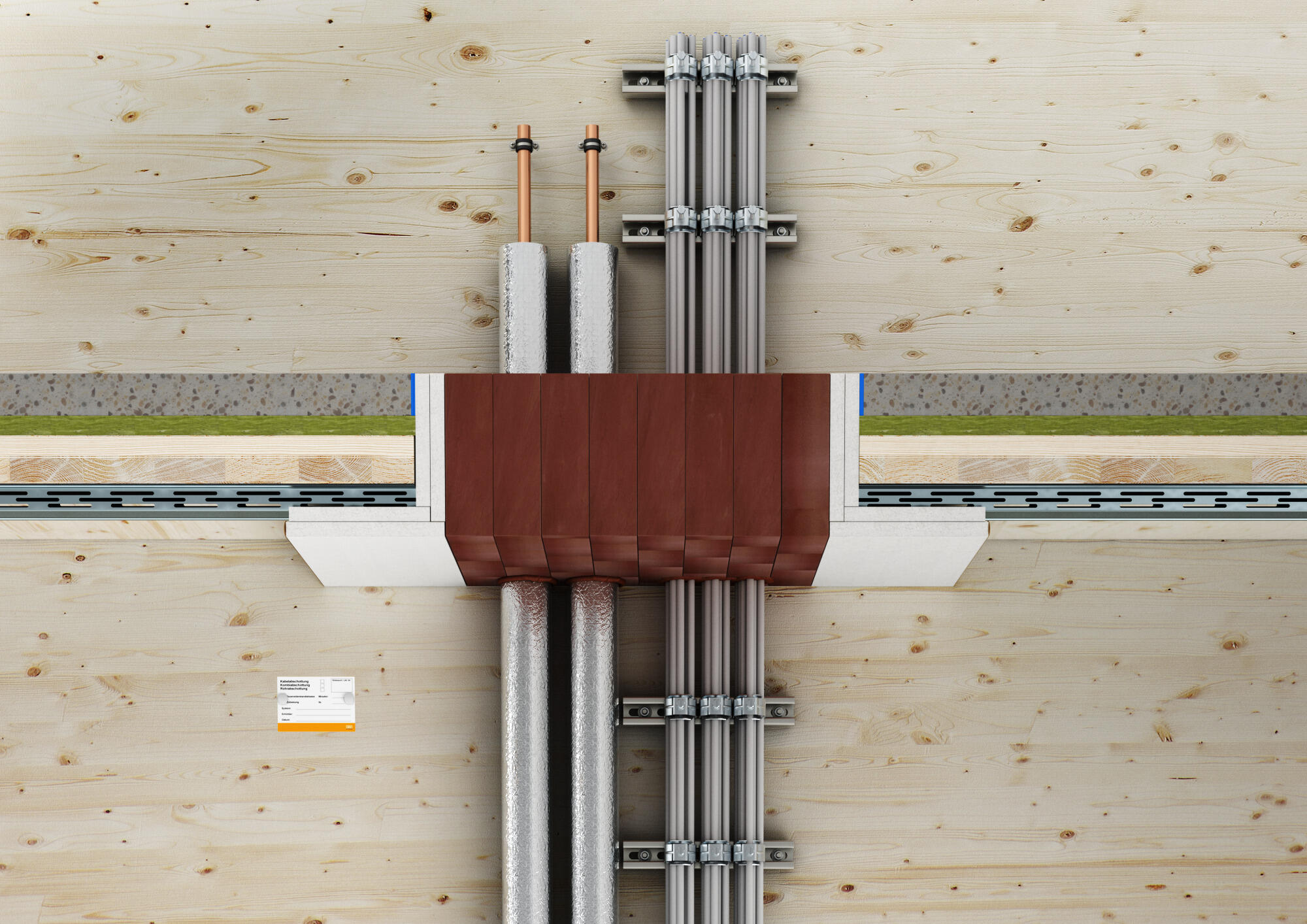

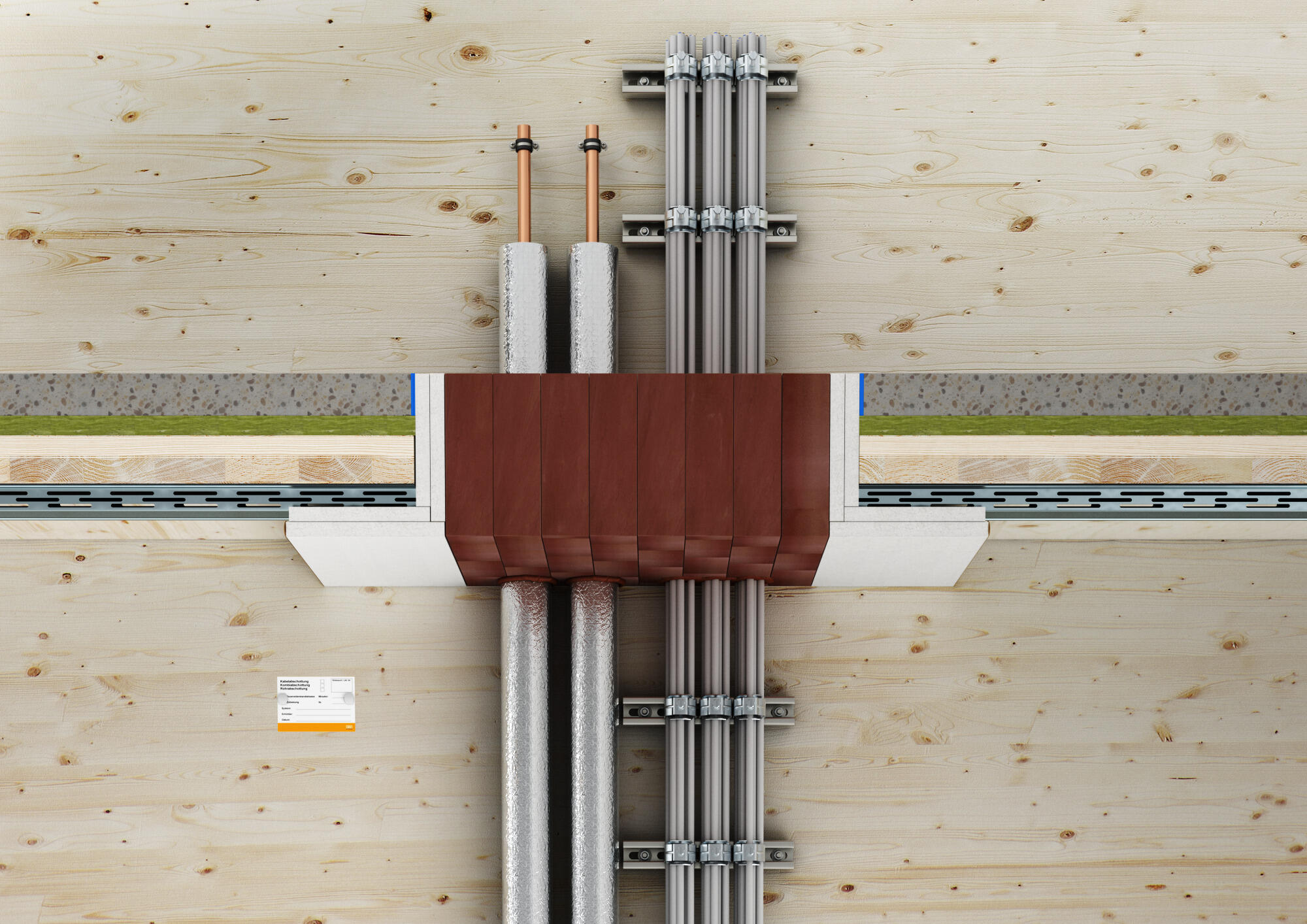

If electrical installations in wooden buildings have to be run through walls and ceilings with a fire resistance period, then they must be insulated, in order to prevent the spread of fire. This can be done using fire protection insulation, which seals ceiling and wall penetrations reliably against fire and smoke with a soffit of non-combustible material. This achieves another important protection aim: namely, the maintenance of fire sections to prevent fire from spreading to parts of the building that are not affected directly.

The insulation products from OBO Bettermann offer comprehensive protection for the maintenance of fire sections – particularly for wooden components. This is confirmed by a new fire protection survey by the IBB engineering office and the engineers Dr Peter Nause and Cord Meyerhoff.

The following systems achieve a fire resistance duration of 30, 60 or 90 minutes with a fire load according to DIN 4102-2 or DIN EN 13501-2:

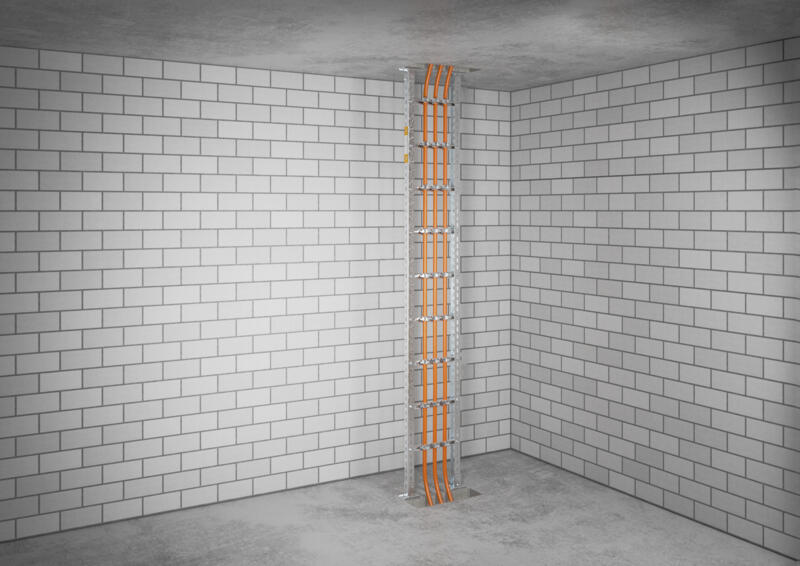

Example fire insulation with insulation systems from OBO Bettermann.

Downloads

You might also find this interesting

Certified fire protection: safe solutions for safe buildings

Whether proofs of application or test and classification standards – we help you stay on top of things.

Fire protection competence: With OBO, you are always on the safe side

With our extensive product range, we offer solutions for all the main protection aims in case of fire.

Suspended vertical ladders: function maintenance according to DIN 4102

The suspended vertical ladder from the OBO portfolio is approved as a standard support structure in accordance with DIN 4102 Part 12.